Introduction

Accurate wind speed measurement is critical to industries such as aviation, marine navigation, renewable energy, and weather forecasting. Traditional anemometers have served their purpose well, but ultrasonic wind sensors are revolutionizing the field with their accuracy, durability, and advanced technology. In this blog, we will explore what ultrasonic wind speed sensors are, how they work, and why they are the preferred choice for wind speed monitoring.

What Is an Ultrasonic Wind Sensor?

An ultrasonic wind sensor, also known as an ultrasonic anemometer, measures wind speed and direction using high-frequency sound waves. Unlike traditional cup or vane anemometers, ultrasonic sensors have no moving parts, making them more durable and maintenance-free.

How Does an Ultrasonic Wind Sensor Work?

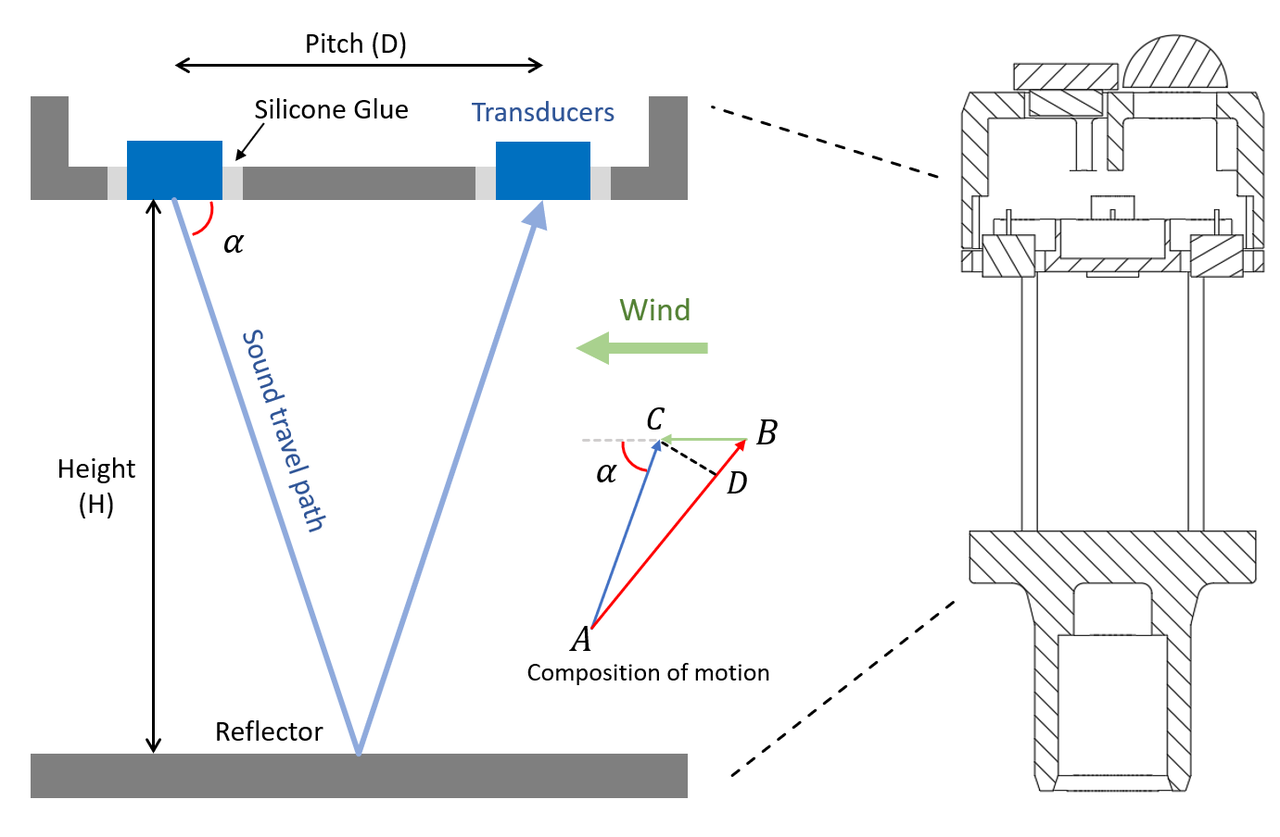

Ultrasonic wind sensors operate by emitting sound waves between multiple transducers. Here’sthesimplified explanation:

Essentially, the principle is as follows: When an ultrasonic wave (pulse) propagates in a flowing medium (air), the wave takes different amounts of time to reach its destination.

The time difference between the forward and reverse propagation reflects the flow velocity of the medium, i.e. the wind speed. The speed of sound is affected by the flow of air relative to the air. Assuming the speed of sound is fixed, the wind speed can be calculated from this.

This innovative approach ensures precision even in harsh environmental conditions.

Advantages of an ultrasonic wind sensor

1. High accuracy

Ultrasonic wind sensor provides accurate measurements in any changing wind conditions, like XF200AS ultrasonic anemometer, accuracy of it is ±(0.3+0.03v)m/s (≤30M/S) ±(0.3+0.05v ) m/s (≥30M/S) v is the standard wind speed.

2. No moving parts

These ultrasonic wind sensors don't have mechanical parts, which can help to reduce maintenance costs.

3. Durability

Ultrasonic wind sensors are made from materials which are weather conditions resistance, it can withstand harsh conditions such as high humidity, salty air, or freezing temperatures.

4. Compact and lightweight design

The integrated design of ultrasonic sensors makes them easy to install with limited space.

5. Advanced data output

Many ultrasonic wind sensors offer different interfaces such as RS485 ModBus, MQTT, SDI-12, or ASCII, which can provide real-time data reading for weather monitoring.

Applications of Ultrasonic Wind Sensors

· Meteorological monitoring

· Micro-environmental monitoring

· Grid environmental monitoring

· Agricultural meteorological monitoring

· Traffic weather monitoring

· Photovoltaic environment monitoring

· Wind power generation weather monitoring

1. New Energy

2. Marine and Navigation

3. Weather Forecast

4. Industrial Safety

5. Drone and Unmanned Aircraft Applications

Choose the right ultrasonic wind speed sensor

When choosing an ultrasonic wind speed sensor, the following factors need to be considered:

-

Range and accuracy requirements:

Make sure the sensor meets the accuracy required by the application. The range of our XF series wind speed and direction sensor is 0-60m/s, and 75m/s can be customized. The accuracy of it is ±(0.3+0.03v)m/s (≤30M/S) ±(0.3+0.05v ) m/s (≥30M/S) v is the standard wind speed.

-

Environmental conditions:

Look for weatherproof and corrosion-resistant models suitable for outdoor use. The sensor must be able to adapt to extreme weather, such as extreme high temperature and extreme low temperature. The operating temperature of our XF series weather station is minus 40 degrees Celsius to 85 degrees Celsius.

-

Output options:

The selected sensor must be compatible with the existing platform protocol. Our default RS485 ModBus protocol can also be customized according to customer requirements. MQTT, ASCII, SDI-12 and other protocols.

-

Budget:

Although ultrasonic sensors may be more expensive than traditional mechanical wind speed and direction sensors, their long-term benefits often outweigh the initial cost.

-

Voltage:

The selected sensor should be the same voltage as the current one to avoid no communication due to low voltage or burning the device due to high voltage.

Ultrasonic wind sensor installation tips

-

Choose an open location:

Install the sensor in an unobstructed area, avoid installing it under trees or near tall buildings to obtain the best wind speed measurement effect.

-

Installation:

Our ultrasonic wind speed and direction sensors come with a flange.

-

Strictly follow the user instructions:

We will send customers user instructions, U-to-485 and our demo software to help customers better set up ultrasonic wind speed and direction sensors.

-

Regular maintenance:

Keep the sensor clean, especially the ultrasonic probe part, to avoid affecting the accuracy of the data.

FAQs

1.Q:How are ultrasonic wind sensors different from traditional anemometers?

A:Ultrasonic wind sensors have no moving parts, making them more durable and more accurate than mechanical anemometers.

2.Q:Are ultrasonic wind sensors suitable for extreme weather?

A:Yes, most ultrasonic sensors are able to withstand harsh environments, including storms, extremely cold weather, extreme heat, and salty air. For example, our ultrasonic wind speed and direction sensors have an operating temperature of -40℃ to 80℃.

3.Q:What is the price range of ultrasonic wind speed sensors?

A:Prices range from $200 to $2,000, depending on features and manufacturing quality.

Choosing our ultrasonic wind speed and direction sensors, you will get a good and affordable product. We provide you with the best quality at a competitive price.

EN

EN

AR

AR

BG

BG

HR

HR

FR

FR

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

ID

ID

VI

VI

TH

TH